Technology of frozen sugarcane production of Truc Lam Phat company

Frozen sugarcane is increasingly popular in the market, especially in the US, Russia, etc. Product quality is also increasingly stricter. Therefore, frozen sugarcane production techniques must be thoroughly researched and applied to ensure product quality.

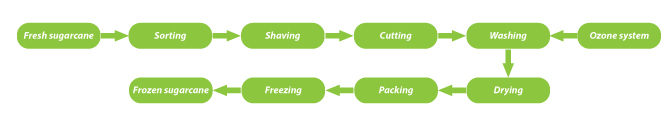

1. PRODUCTION PROCESS OF FROZEN SUGARCANE

Fresh sugarcane

Fresh sugarcane of our company uses to produce frozen sugarcane is the white sugarcane ROC 16. This sugarcane is rather hard but the sweetness is quite high. Therefore, this type of sugarcane is quite suitable for squeezing sugarcane juice.

Sorting

Sugarcane after being bought to the factory will be sorted to ensure that the quality of sugarcane is always okay for producing.

See more information of production process of frozen sugarcane here

Shaving

The sugarcane is put into the peeler to completely remove the outer silk layer. Peeling capacity about 1-2 tons/hour.

Cutting

After shaving, sugarcane will be cut into pieces according to the requirements of customers. Normally, the size of sugarcane is cut from 40 to 50 cm/tree

Washing

After being cut, sugarcane is put through a sink with ozone system to disinfect the surface of sugarcane. Washing time from 15-20 minutes

If you need quality frozen sugarcane products, contact us right here

Drying

After being picked out, the cane will be put on a drying rack to dry, ensuring that they are completely dry before packing.

Packing

Cane after cutting is packed according to each required specification. They are packed in PE bags and 5-layer cartons.

Freezing

Sugarcane is frozen at a temperature of -21 degrees Celsius in 48 hours, with this temperature ensuring the center of the product reaches -18 degrees Celsius.

This article is the production process of frozen sugarcane of Truc Lam Phat Trading Service Co., Ltd. Our company always ensures to produce safe and quality frozen sugarcane products.

Source: Truclamphatagri.com

References

Vietnamese sugarcane exports to the Danish market

Export frozen sugarcane to the American market

Leave a comment